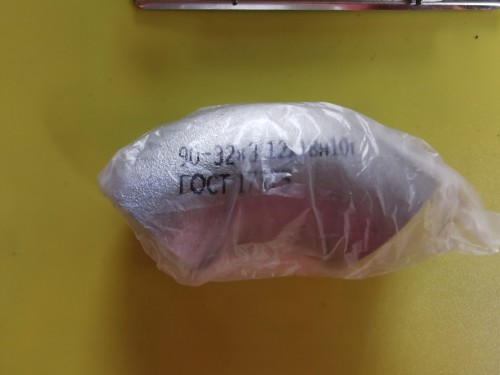

ELBOW 12Х18Н10Т/321

Angles: θ = 45°, θ = 60°, θ = 90°, θ = 180°

Materials: Stainless Steel, Alloy Steel, Carbon Steel, Nickel Alloys, Copper Alloys, Titanium Alloys.

Standard: ГОСТ 17375-2001.

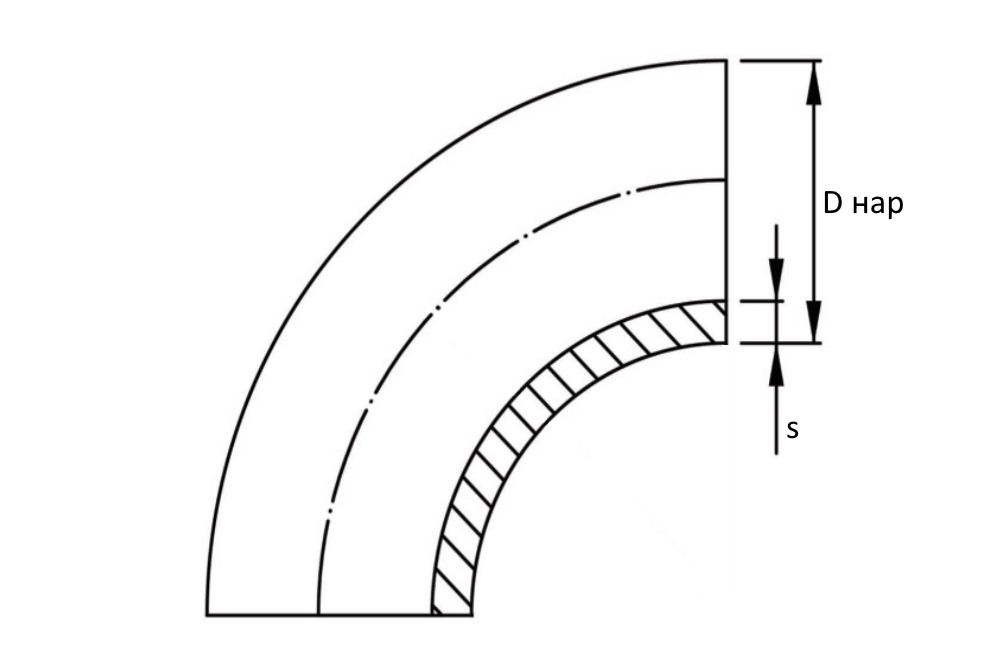

Diameter: DN15mm – DN800mm.

Wall Thickness: From 2 mm to 40 mm (SCH5S – XXS).

Radius: R = 1D – 10D; R = 15D, 20D; R = 1.5D.

Pressure Rating: Up to 16 MPa.

Temperature: Up to +600°C.

Type: Seamless welded.

Working Media: Water, steam, oil, gas, etc.

The 12Х18Н10Т (AISI 321) Elbow is a key component used to alter the direction of flow in various piping systems. This fitting is made from high-quality heat-resistant stainless steel, offering excellent performance under extreme conditions, such as high temperatures and pressures, and is resistant to aggressive environments.

- Durability: High resistance to temperature changes and corrosion.

- High-Temperature Resistance: Suitable for applications with temperatures up to 600°C.

- Pressure Resistance: Rated to withstand up to 16 MPa pressure.

- Wide Application: Commonly used in industries such as water, steam, oil, and gas.

Manufacturing Options

The elbows can be made from the following materials:

- Stainless Steel: AISI 304, 304L, 316, 316L, 321, 347, 08Х18Н10, 12Х18Н10Т, 20Х23Н13, 10Х17Н13М2Т, etc.

- Carbon Steel: ASTM A234 (WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65, WPHY 70).

- Low-Temperature Carbon Steel: ASTM A420 (WPL3, WPL6).

- Alloy Steel: ASTM A234 (Gr. WP1, WP5, WP9, WP11, WP91).

- Duplex Steel: ASTM A815 (UNS S31803, S32205).

- Nickel Alloys: ASTM/ASME SB 336 UNS 2200 (Nickel 200), UNS 2201 (Nickel 201), UNS 4400 (Monel 400), UNS 8020 (Alloy 20/20 CB 3), UNS 8825 (Inconel 825), UNS 6600 (Inconel 600), UNS 6601 (Inconel 601), UNS 6625 (Inconel 625), UNS 10276 (Hastelloy C276).