SPIRAL WOUND GASKET

Products are manufactured in accordance with all relevant gasket standards.

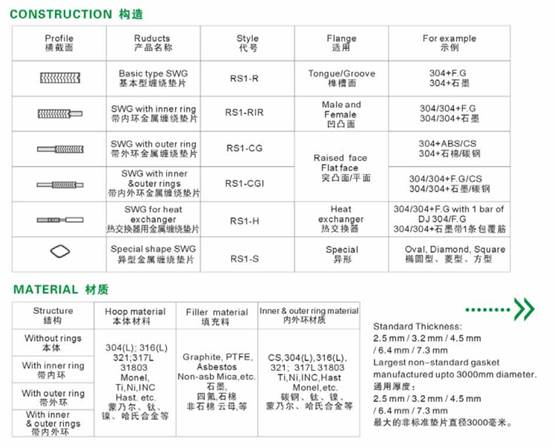

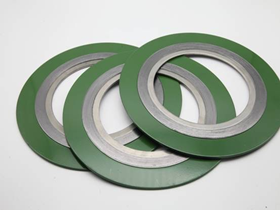

All types of Spiral wound gaskets can be manufactured, CG, CGI, R, RIR, etc.

Our production capacity is 350,000 pcs per month.

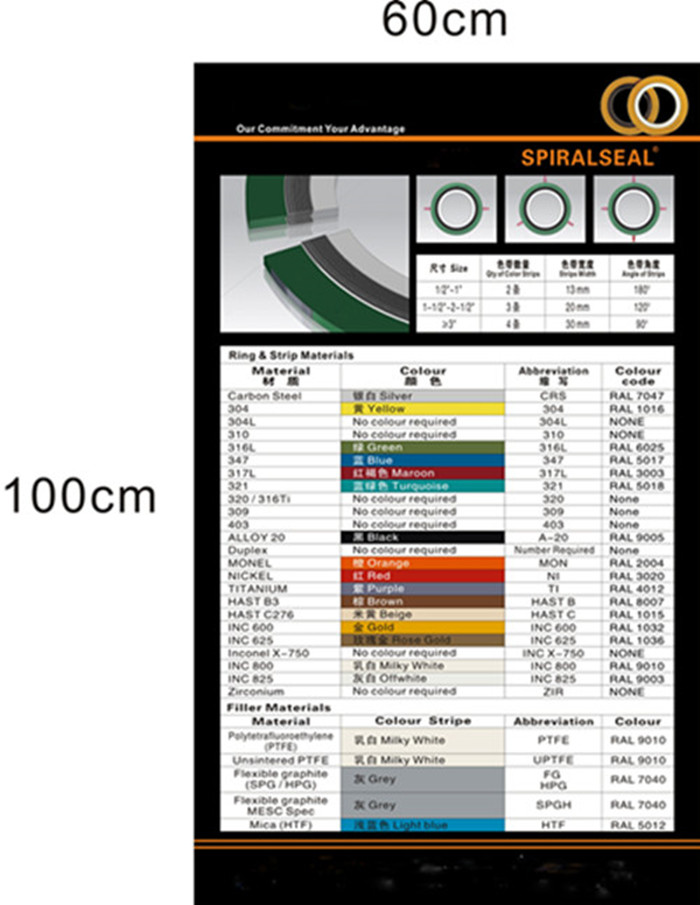

Material combinations for all operating conditions.

Standard Spiral Wound Gasket

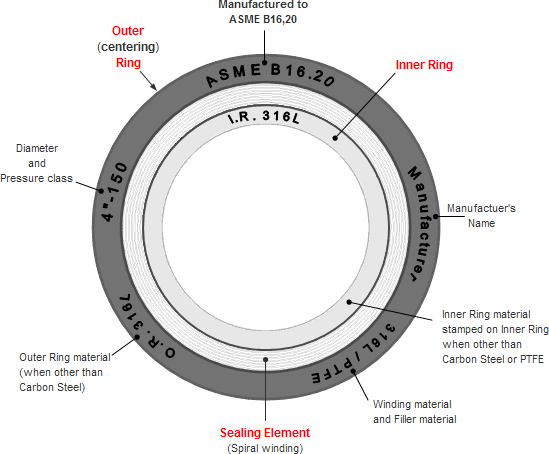

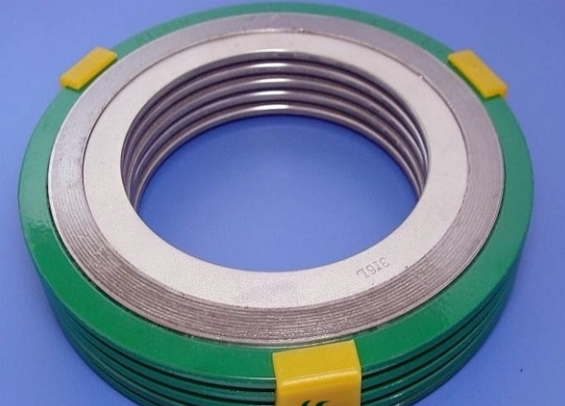

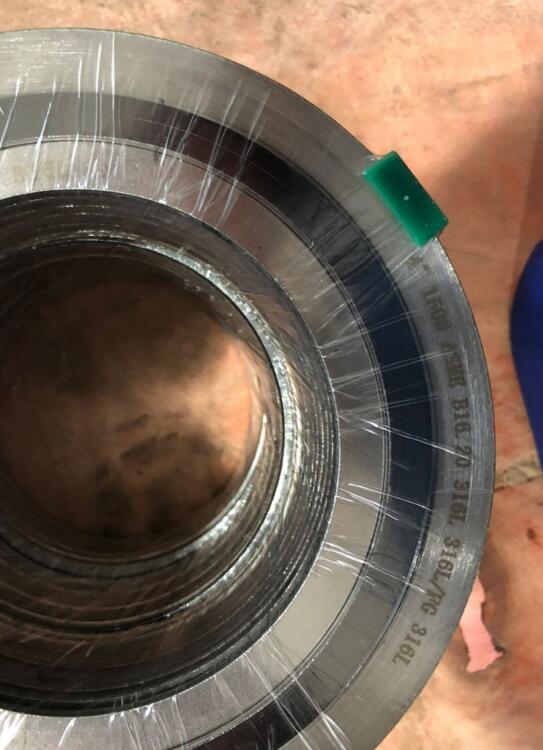

A spiral wound gasket may include a centering ring, an inner ring or both. The outer centering ring enters the gasket within the flange and acts as a compression limiter, Moreover, centering ring of each spiral wound gasket shall be permanently marked. We can stamping according to customer’s request (Manufacture’s name or trademark/flange size/pressure class/detail composition of gasket/ flange identification/ ASME B16.20 designation etc).

The inner ring provides additional radial strength. It also reduces flange erosion and protects the sealing element. Resilience and strength make spiral wound gaskets an ideal choice under a variety of conditions and applications. As environmental regulations and industry requirements become increasingly stringent, new and custom applications are continuing to evolve. Whenever you need a strong, resilient seal, our spiral wound gaskets will provide an effective solution.

Products are manufactured in accordance with all relevant gasket standards to suit flange designations: ASME B 16.20, MSS SP-44, API 605, DIN 2632-2638/ DIN EN1514-2, JIS B2404, BS EN1514-2 , etc. Or products can be customized according to the users’ requirements(no-standard spiral wound gasket). Please provide the specific drawings if the gasket is no-standard.

Following is the prime feature for spiral wound gasket:

1.Gasket are made in a wide variety of sizes and shapes.

2.Combinations of metal strip and filler are selected to suit the specific fluid media and operating conditions.

3.Quick to install and remove

4.Make gaskets suitable for high pipeline pressure on flat or raised flange faces.

5. High and low temperature resistant