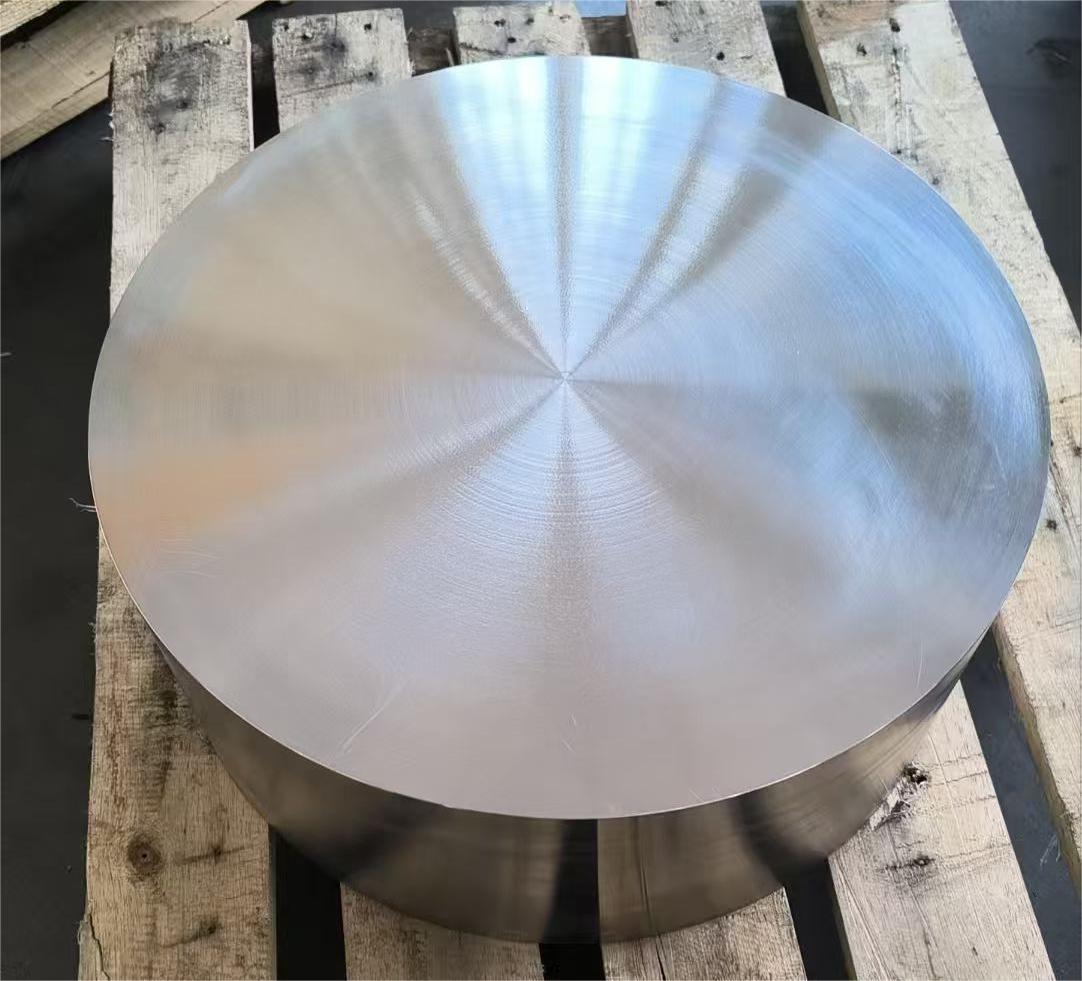

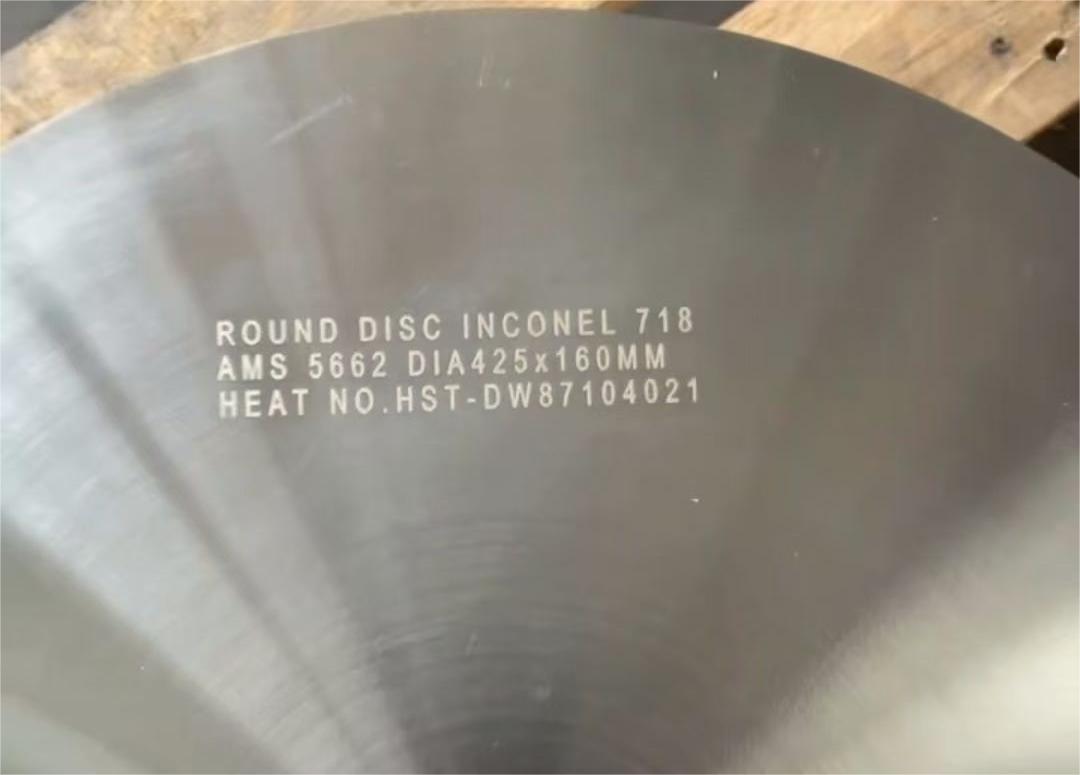

Inconel 718 Bar AMMS5662

Inconel 718 Bar AMMS5662

Alloy 718 (UNS N07718, W Nr 2.4668) is an austenitic nickel-based superalloy. Alloy 718 exhibits excellent high yield tensile and creep-rupture properties at temperatures up to 1300ºF and oxidation resistance to 1800ºF. Alloy 718 is used in applications that require high strength such as parts for jet engines and high speed airframe parts such as wheels, buckets, spacers and high temperature bolts and fasteners.

|

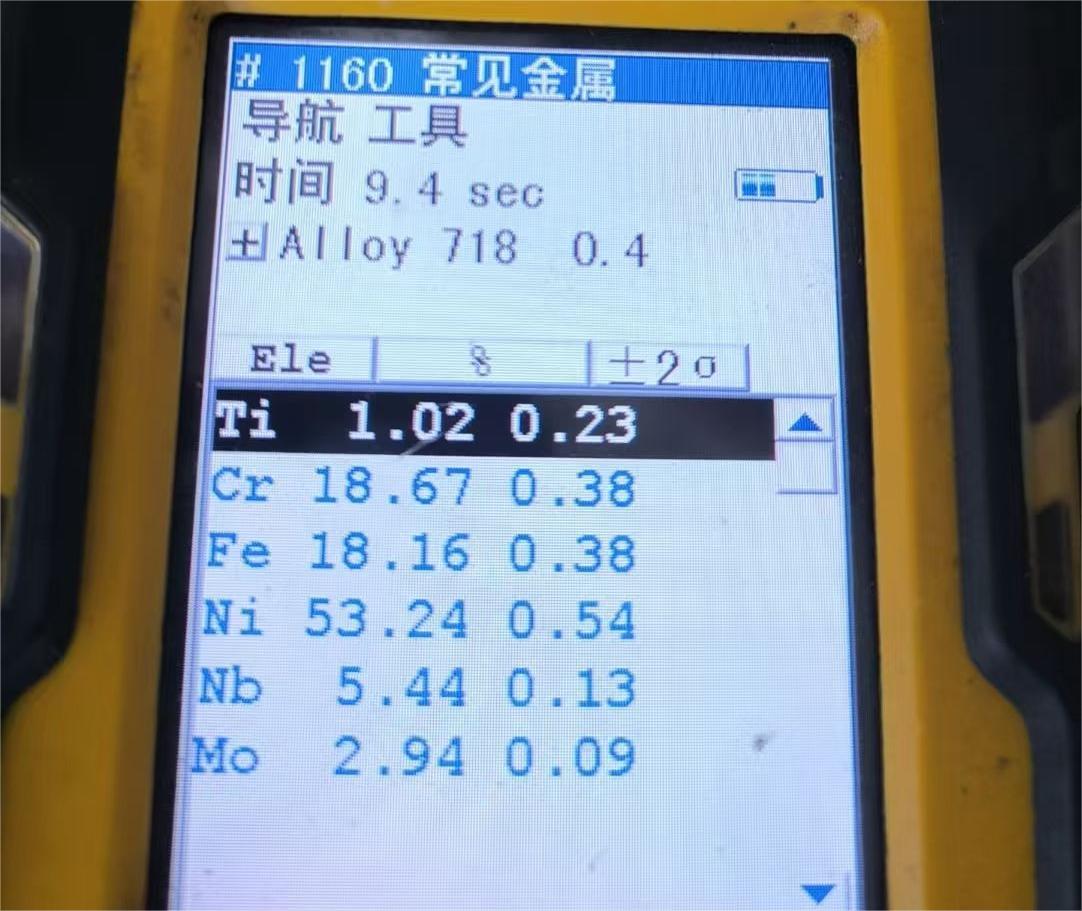

Chemical Composition Limits |

||||||||||||||||

|

Weight % |

C |

Mn |

P |

S |

Si |

Cr |

Ni |

Mo |

Cb |

Ta |

Ti |

Al |

Co |

B |

Cu |

Fe |

|

Alloy 718 |

0.08 |

0.35 |

0.015 |

0.015 |

0.35 |

17-21 |

50-55 |

2.8-3.30 |

4.75-5.50 |

0.05 |

0.65-1.15 |

0.20-0.80 |

1 |

0.006 |

0.3 |

Rem |

|

AMS 5662 |

||||||||||||||||

There are two main types of solution annealed and aging treatments:

Solution Treatment (AMS 5662 Bar / AMS 5596 Sheet): 1725°F - 1850°F + Air Cool.

Heat Treatment (AMS 5663 Bar) : 1325°F for 8 hrs, cooling 100°F/hr to 1150°F, hold at 1150°F for 8hrs min, + Air Cool .

This treatment gives the highest room temperature tensile and yield strengths as well as producing the highest fatigue strength. It is the optimum heat treatment for Alloy 718 where a combination of rupture life, notch rupture life and rupture ductility is required.

Alternative Solution Treatment (AMS 5664 Bar / AMS 5597 Sheet): 1900°F - 1950°F + Air Cool

Heat Treatment: 1400°F for 10hrs, furnace cool to 1200°F, hold at 1200°F for a total aging time of 20 hrs + Air Cool.

This is the prefered treatment in tensile-limited applications as it produces the best transverse ductility in heavy sections, impact strength and low temperature notch tensile strength. However, this treatment has a tendency to produce notch brittleness in stress rupture.

|

Material |

Condition |

Tensile Strength |

Yield Strength |

Elongation |

Reduction of Area |

Hardness |

|

ksi |

ksi |

4D |

% |

|||

|

AMS 5662 Bar |

1700-1850°F Anneal |

- |

- |

- |

- |

≤ 277 HB |

|

AMS 5663 Bar |

1700-1850°F Anneal + Age |

185 |

150 |

12 |

15 |

≥331 HB |

|

AMS 5664 Bar |

1900-1950°F Anneal |

- |

- |

- |

- |

3" dia 248 HB |

|

3-5" dia 285 HB |

||||||

|

|

1900-1950°F Anneal + Age |

180 |

150 |

10 |

12 |

≥341 HB |