BLIND FLANGE

Material : Stainless steel flange , Alloy Steel flange , Carbon Steel flange ,Nickel steel flange

Production Range : 1/2''-48'' (DN10~DN1200)

Pressure: 150#, 300#,400 #,600#,900#, 1500# & 2500 #,PN6-PN250

Standard: ASTM, DIN, EN, GOST ,JIS ,GB

Blind Flanges

ANSI -ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, ANSI B16.48

DIN-DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636, DIN2637, DIN2638, DIN2673 ,EN1092-1

B.S-BS4504 , BS4504, BS1560, BS10

Фланцы по ГОСТ 12820-80, ГОСТ 12821-80,ГОСТ 28759.3-90, ГОСТ 28759.4-90

Заглушки фланцевые (АТК 26-18-5-93, АТК 24.200.02-90, ТММ-25-01-06-01, ТММ-25-01-06-02(03)

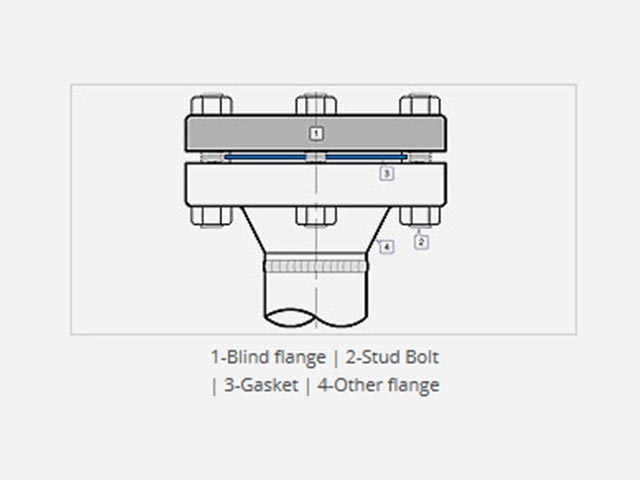

These flat face steel blind flanges are used to blank off pipelines, valves and pumps, it can also be used as an inspection cover. Blind flange is sometimes referred to as a blanking flange. Experienced professionals are engaged with us who fabricate these flanges with excellent precision. We are recognized blind flanges manufacturer.

|

ANSI B 16.5 Class 150 |

ANSI B 16.5 Class 300 |

ANSI B 16.5 Class 600 |

|

ANSI B 16.5 Class 900 |

ANSI B 16.5 Class 1500 |

ANSI B 16.5 Class 2500 |

Stainless Steel

ASTM A 182, A 240

Grade

F304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H,904L,

Duplex stainless steel UNS S31803, 2205, Super Duplex stainless steel UNS

S32750

Carbon Steel

ASTM A 105, ASTM A 181

Alloy Steel

ASTM A 182, GR F1, F11, F22, F5, F9, F91

Nickel Alloys

Monel 400 & 500, Inconel 600 & 625, Incolloy 800, 825, Hastelloy

C22,C276

Copper Alloys

Copper, Brass & Gunmetal

Size

1/8" NB TO 48"NB.

Class

150#, 300#,400 #,600#,900#, 1500# & 2500 #.

ANSI

ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, ANSI B16.48

DIN

DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656,

DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635,

DIN2636, DIN2637, DIN2638, DIN2673

B.S

BS4504 , BS4504, BS1560, BS10

Raw Material :

Click here to view the Flange Tolerances

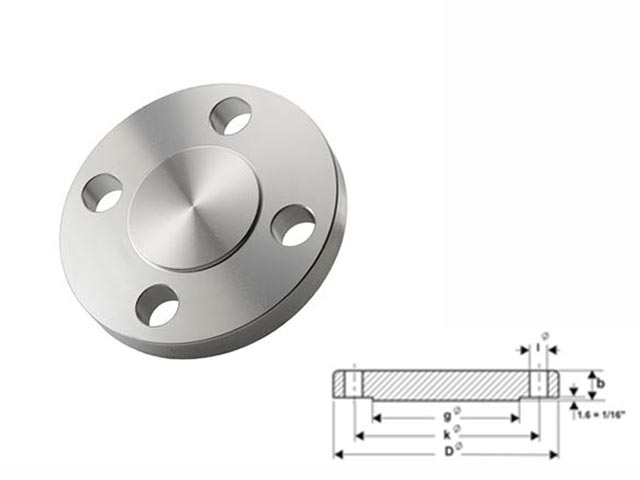

150 lb. Dimensions

|

Nominal Pipe size |

Flange |

Raised Face g mm. Inches |

Drilling Template |

Approx. weight Kg. Pounds |

|||

|

D mm. Inches |

b mm. Inches |

Number |

l mm. Inches |

k mm. Inches |

|||

|

1/2″ |

88.9 |

11.1 |

34.9 |

4 |

15.9 |

60.3 |

0.5 |

|

3 1/2 |

7/16 |

1 3/8 |

5/8 |

2 3/8 |

1 |

||

|

3/4″ |

98.4 |

12.7 |

42.9 |

4 |

15.9 |

69.8 |

0.9 |

|

3 7/8 |

1/2 |

1 11/16 |

5/8 |

2 3/4 |

2 |

||

|

1″ |

108 |

14.3 |

50.8 |

4 |

15.9 |

79.4 |

0.9 |

|

4 1/4 |

9/16 |

2 |

5/8 |

3 1/8 |

2 |

||

|

11/4″ |

117.5 |

15.9 |

63.5 |

4 |

15.9 |

88.9 |

1.4 |

|

4 5/8 |

5/8 |

2 1/2 |

5/8 |

3 1/2 |

3 |

||

|

11/2″ |

127 |

17.5 |

73 |

4 |

15.9 |

98.4 |

1.8 |

|

5 |

11/16 |

2 7/8 |

5/8 |

3 7/8 |

4 |

||

|

2″ |

152.4 |

19.1 |

92.1 |

4 |

19 |

120.6 |

2.3 |

|

6 |

3/4 |

3 5/8 |

3/4 |

4 3/4 |

5 |

||

|

21/2″ |

177.8 |

22.2 |

104.8 |

4 |

19 |

139.7 |

3.2 |

|

7 |

7/8 |

4 1/8 |

3/4 |

5 1/2 |

7 |

||

|

3″ |

190.5 |

23.8 |

127 |

4 |

19 |

152.4 |

4.1 |

|

7 1/2 |

15/16 |

5 |

3/4 |

6 |

9 |

||

|

31/2″ |

215.9 |

23.8 |

139.7 |

8 |

19 |

177.8 |

5.9 |

|

8 1/2 |

15/16 |

5 1/2 |

3/4 |

7 |

13 |

||

|

4″ |

228.6 |

23.8 |

157.2 |

8 |

19 |

190.5 |

7.7 |

|

9 |

15/16 |

6 3/16 |

3/4 |

7 1/2 |

17 |

||

|

5″ |

254 |

23.8 |

185.7 |

8 |

22.2 |

215.9 |

9.1 |

|

10 |

15/16 |

7 5/16 |

7/8 |

8 1/2 |

20 |

||

|

6″ |

279.4 |

25.4 |

215.9 |

8 |

22.2 |

241.3 |

11.8 |

|

11 |

1 |

8 1/2 |

7/8 |

9 1/2 |

26 |

||

|

8″ |

342.9 |

28.6 |

269.9 |

8 |

22.2 |

298.4 |

21 |

|

13 1/2 |

1 1/8 |

10 5/8 |

7/8 |

11 3/4 |

46.2 |

||

|

10″ |

406.4 |

30.2 |

323.8 |

12 |

25.4 |

361.9 |

31.8 |

|

16 |

1 3/16 |

12 3/4 |

1 |

14 1/4 |

70 |

||

|

12″ |

482.6 |

31.8 |

381 |

12 |

25.4 |

431.8 |

49.9 |

|

19 |

1 1/4 |

15 |

1 |

17 |

110 |

||

|

14″ |

533.4 |

34.9 |

412.7 |

12 |

28.6 |

476.2 |

63.5 |

|

21 |

1 3/8 |

16 1/4 |

1 1/8 |

18 3/4 |

140 |

||

|

16″ |

596.9 |

36.5 |

469.9 |

16 |

28.6 |

539.7 |

81.6 |

|

23 1/2 |

1 7/16 |

18 1/2 |

1 1/8 |

21 1/4 |

180 |

||

|

18″ |

635 |

39.7 |

533.4 |

16 |

31.7 |

577.8 |

99.8 |

|

25 |

1 9/16 |

21 |

1 1/4 |

22 3/4 |

220 |

||

|

20″ |

698.5 |

42.9 |

584.2 |

20 |

31.7 |

635 |

129 |

|

27 1/2 |

1 11/16 |

23 |

1 1/4 |

25 |

285 |

||

|

22″ |

749.3 |

46 |

641.2 |

20 |

34.9 |

692.1 |

161 |

|

29 1/2 |

1 13/16 |

25 1/4 |

1 3/8 |

27 1/4 |

355 |

||

|

24″ |

812.8 |

47.6 |

692.1 |

20 |

34.9 |

749.3 |

195 |

|

32 |

1 7/8 |

27 1/4 |

1 3/8 |

29 1/2 |

430 |

||

Click to download Stainless Steel Blind Flanges PDF

300 lb. Dimensions

|

Nominal Pipe size |

Flange |

Raised Face g mm. Inches |

Drilling Template |

Approx. weight Kg. Pounds |

|||

|

D mm. Inches |

b mm. Inches |

Number |

l mm. Inches |

k mm. Inches |

|||

|

1/2″ |

95.2 |

14.3 |

34.9 |

4 |

15.9 |

66.7 |

0.9 |

|

3 3/4 |

9/16 |

1 3/8 |

5/8 |

2 5/8 |

2 |

||

|

3/4″ |

117.5 |

15.9 |

42.9 |

4 |

19 |

82.5 |

1.4 |

|

4 5/8 |

5/8 |

1 11/16 |

3/4 |

3 1/4 |

3 |

||

|

1″ |

123.8 |

17.5 |

50.8 |

4 |

19 |

88.9 |

1.4 |

|

4 7/8 |

11/16 |

2 |

3/4 |

3 1/2 |

3 |

||

|

11/4″ |

133.3 |

19 |

63.5 |

4 |

19 |

98.4 |

1.8 |

|

5 1/4 |

3/4 |

2 1/2 |

3/4 |

3 7/8 |

4 |

||

|

11/2″ |

155.6 |

20.6 |

73 |

4 |

22.2 |

114.3 |

2.7 |

|

6 1/8 |

13/16 |

2 7/8 |

7/8 |

4 1/2 |

6 |

||

|

2″ |

165.1 |

22.2 |

92.1 |

8 |

19 |

127.5 |

3.6 |

|

6 1/2 |

7/8 |

3 5/8 |

3/4 |

5 |

8 |

||

|

21/2″ |

190.5 |

25.4 |

104.8 |

8 |

22.2 |

149.2 |

5.4 |

|

7 1/2 |

1 |

4 1/8 |

7/8 |

5 7/8 |

12 |

||

|

3″ |

209.5 |

28.6 |

127 |

8 |

22.2 |

168.3 |

7.3 |

|

8 1/4 |

1 1/8 |

5 |

7/8 |

6 5/8 |

16 |

||

|

31/2″ |

228.5 |

30.2 |

139.7 |

8 |

22.2 |

184.1 |

9.5 |

|

9 |

1 3/16 |

5 1/2 |

7/8 |

7 1/4 |

21 |

||

|

4″ |

254 |

31.8 |

157.2 |

8 |

22.2 |

200 |

12.2 |

|

10 |

1 1/4 |

6 3/16 |

7/8 |

7 7/8 |

27 |

||

|

5″ |

279.4 |

34.9 |

185.7 |

8 |

22.2 |

234.9 |

15.9 |

|

11 |

1 3/8 |

7 5/16 |

7/8 |

9 1/4 |

35 |

||

|

6″ |

317.5 |

36.5 |

215.9 |

12 |

22.2 |

269.9 |

22.7 |

|

12 1/2 |

1 7/16 |

8 1/2 |

7/8 |

10 5/8 |

50 |

||

|

8″ |

381 |

41.3 |

269.9 |

12 |

25.4 |

330.2 |

36.7 |

|

15 |

1 5/8 |

10 5/8 |

1 |

13 |

81 |

||

|

10″ |

444.5 |

47.6 |

323.8 |

16 |

28.6 |

387.3 |

57 |

|

17 1/2 |

1 7/8 |

12 3/4 |

1 1/8 |

15 1/4 |

125 |

||

|

12″ |

520.7 |

50.8 |

381 |

16 |

31.7 |

450.8 |

84 |

|

20 1/2 |

2 |

15 |

1 1/4 |

17 3/4 |

181 |

||

|

14″ |

584.2 |

54 |

412.7 |

20 |

31.7 |

514.3 |

113 |

|

23 |

2 1/8 |

16 1/4 |

1 1/4 |

20 1/4 |

250 |

||

|

16″ |

647.7 |

57.2 |

469.9 |

20 |

34.9 |

571.5 |

134 |

|

25 1/2 |

2 1/4 |

18 1/2 |

1 1/8 |

22 1/2 |

295 |

||

|

18″ |

711.2 |

60.3 |

533.4 |

24 |

34.9 |

628.5 |

178 |

|

28 |

2 3/8 |

21 |

1 1/8 |

24 3/4 |

392 |

||

|

20″ |

774.7 |

63.5 |

584.2 |

24 |

34.9 |

685.8 |

229 |

|

30 1/2 |

2 1/2 |

23 |

1 1/8 |

27 |

505 |

||

|

22″ |

838.2 |

66.7 |

641.2 |

24 |

41.3 |

742.9 |

290 |

|

33 |

2 5/8 |

25 1/4 |

1 5/8 |

29 1/4 |

640 |

||

|

24″ |

914.4 |

69.8 |

692.1 |

24 |

41.3 |

812.8 |

358 |

|

36 |

2 3/4 |

27 1/4 |

1 5/8 |

32 |

790 |

||

Wuxi Well Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1) Wuxi Well Standard