API 5L 3PE PIPELINE

Material:Seamless Pipes-A, B, X42, X46, X52, X56, X60, X65 ,X70,X80,PSL1/PSL2

Production Range : 1/4"-100''

Wall Thickness : SCH20,SCH30,SCH40,STD ,SCH80,SCH160,SCHXXS

Standard: API 5L 46ED SPEC 7 11B 11E

Available Specification:

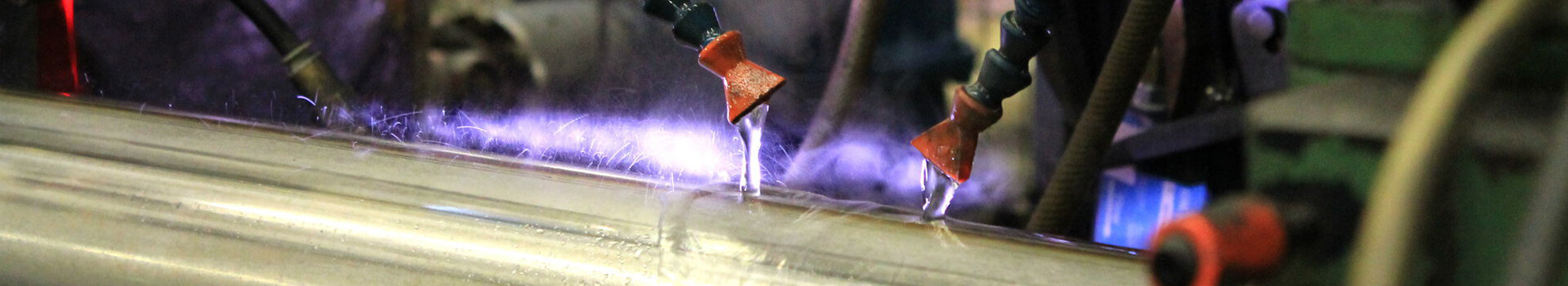

Welded Pipes

Standard: API SPEC 5L

Material/Steel Grade: A, B, X42, X46, X52, X56, X60, X65 ,X70,PSL1/PSL2

Application: conveying water,petroleum/oil,gas,other fluid

Size:

ERW: 8"-24''

LSAW: 16"-64"

SSAW: 8"-100"

Forming: JCOE UOE RBE

Wall Thickness: SCH20,SCH30,SCH40,STD,SCH80,SCH160,SCHXXS

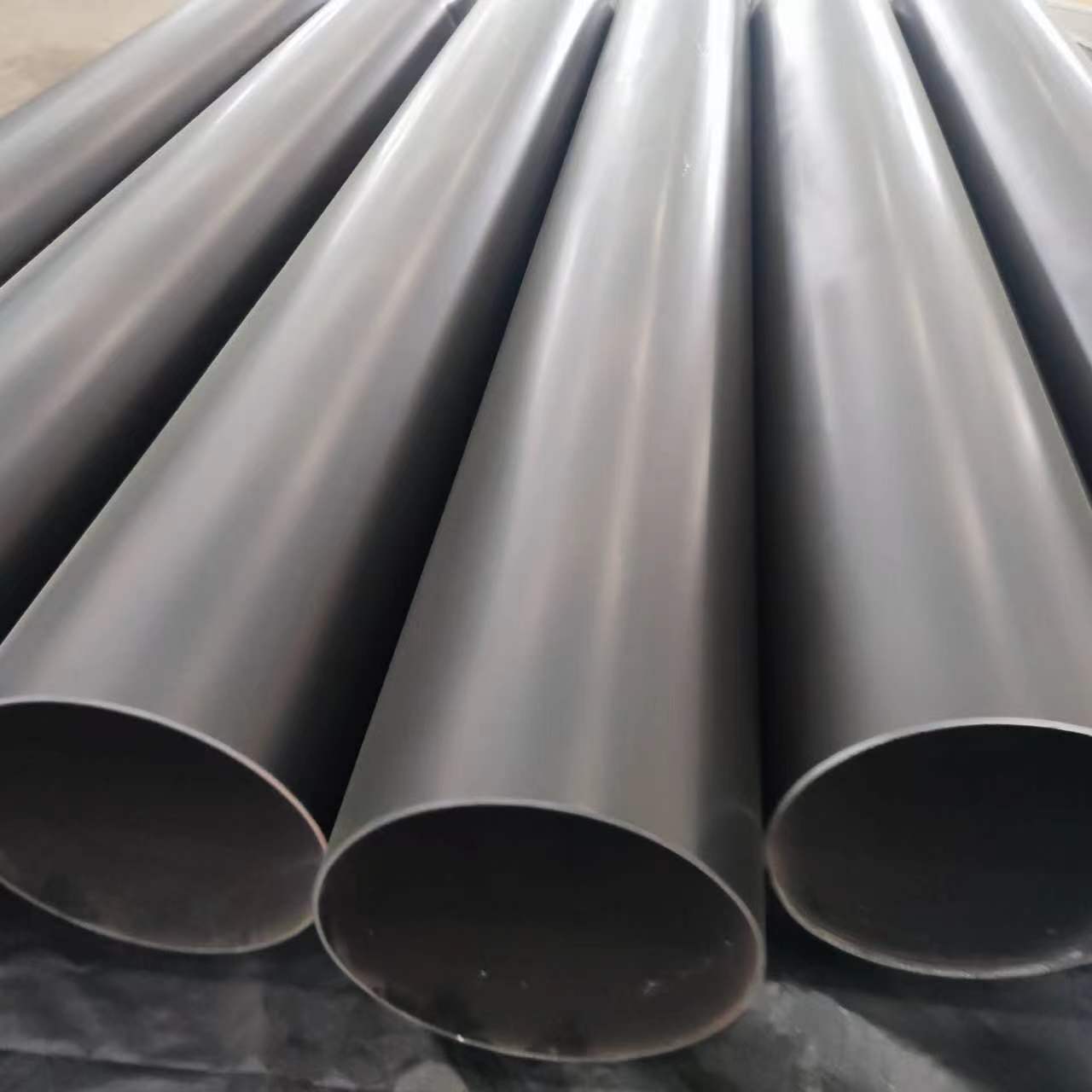

Coating: Bare,Black, 3PE/2PE ,FBE/2FBE,3PP

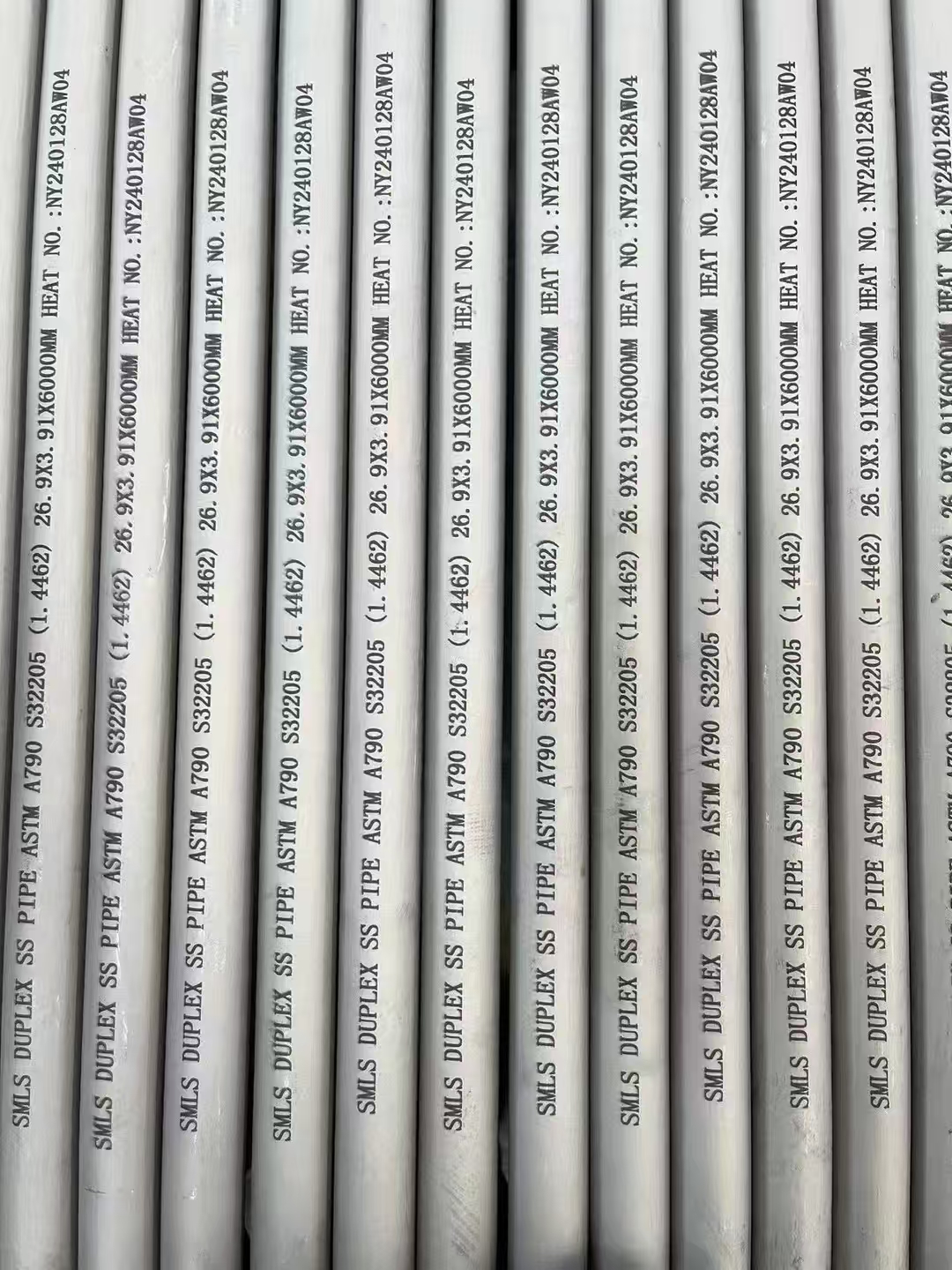

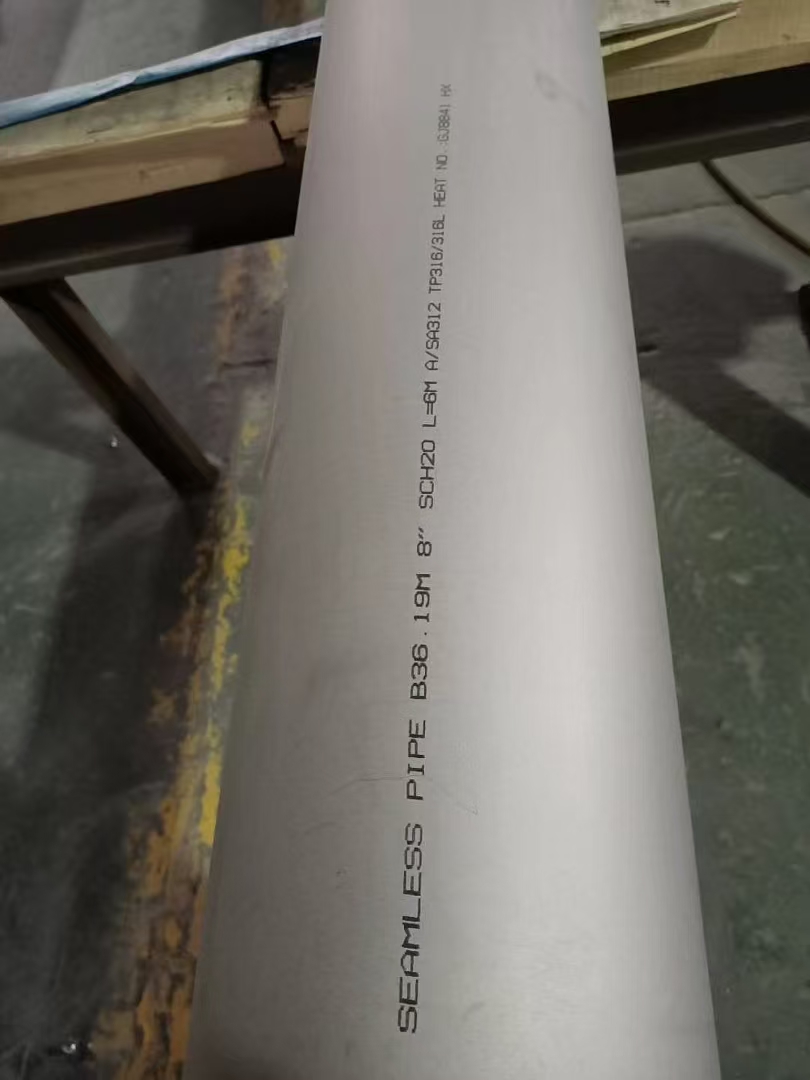

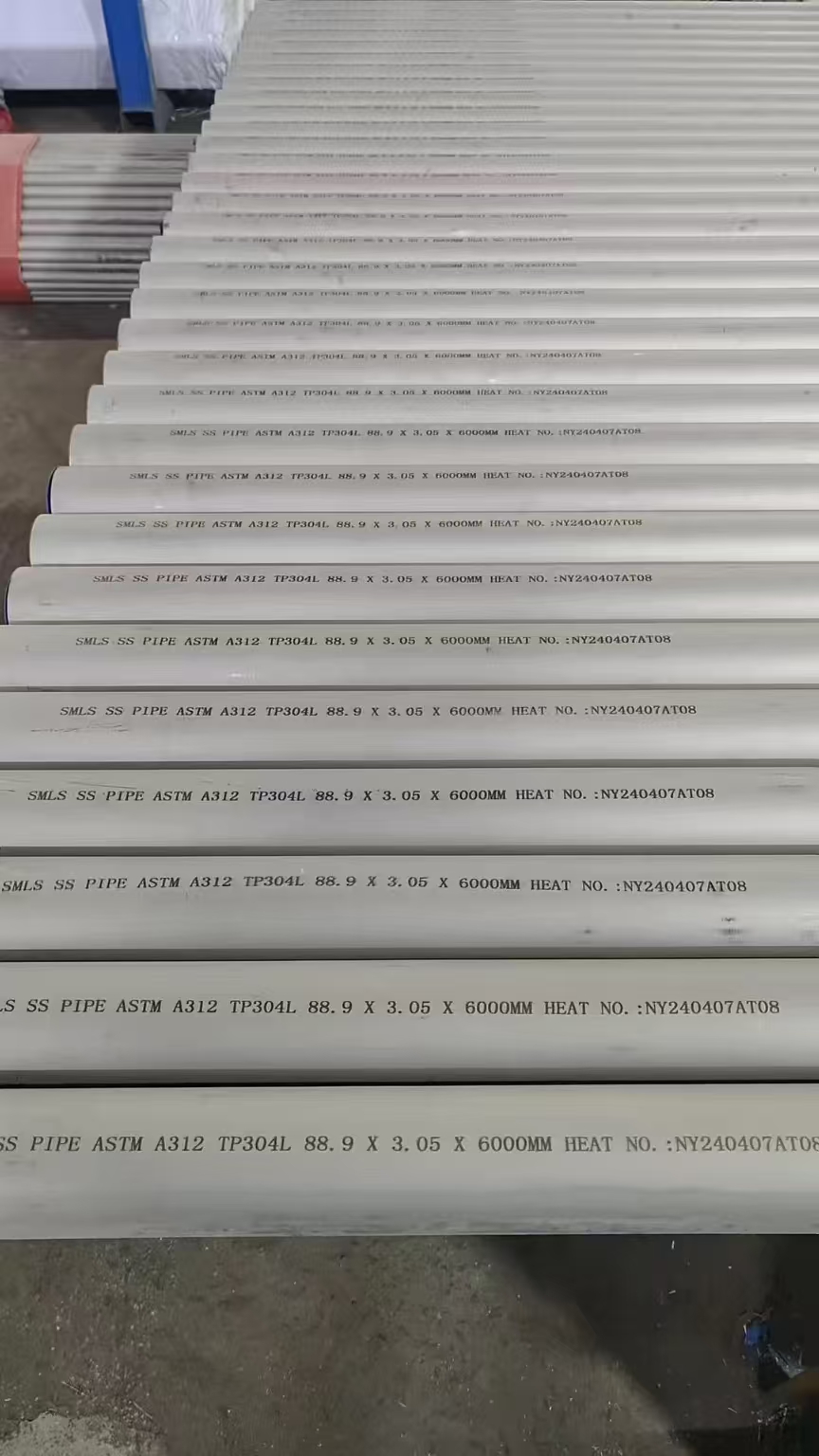

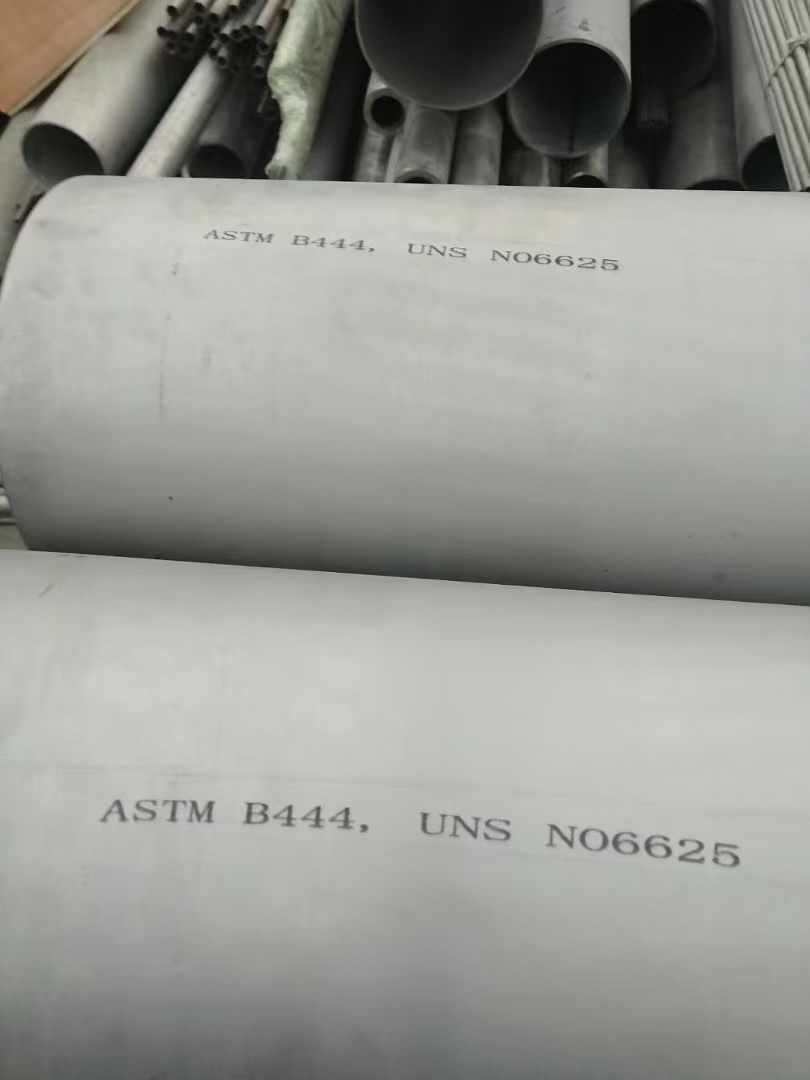

Seamless Pipes

Standard: API SPEC 5L

Material/Steel Grade: A, B, X42, X46, X52, X56, X60, X65 ,X70,X80,PSL1/PSL2

Application: conveying water,petroleum/oil,gas,other fluid

Size: 1/4"-24''

Wall Thickness:SCH20,SCH30,SCH40,SCH80,SCH160,SCH STD

Coating: Black,3PE/2PE ,FBE/2FBE,3PP

Size Range

1/2 to 36 inch NB

Schedule Thickness Range

SCH 40, 80, 160, XS, XXS, All Schedules

Applications

Oil Refineries, Power Generation, Petrochemicals, Sugar, Pressure Vessels, Boiler Equipments, General Engineering Purposes

Pipe Type

Seamless, ERW, Welded, Fabricated, CDW

Pipe & Tube Form

Round, Square, Rectangular, Coiled, “U” Shape, Pan Cake Coils, Hydraulic Tubes

Length:

Single, Double Random & Length, Custom Size – 12 M lengths

End:

Beveled End, Plain End, Treaded

End Protection:

Plastic Caps

End Connections for Line Pipes

Plain, Bevel, Screwed, Threaded

Outside Coating

Black Painting, Anti-Corrosion Oil, Galvanised Finish

The finishes range as plain, bevel ended, screwed and threaded pipes. The length of the pipes vary from single random, double random to required and custom lengths as cut to sizes. The API 5L Grade B Welded Pipe has high absolute roughness than the seamless pipes. The seamless pipes can be used for more dimensionally accurate applications. The pipes can also be manufactured through hot rolling and cold drawing procedures. The API 5L Grade B PSL1 Line Pipe can come in different coatings such as fusion bond epoxy resin coated, galvanized, sand blasted, machined and other types. The API 5L Gr B PSL2 Pipe has higher mechanical properties than the PSL 1 pipes and these are used for higher stress applications. The material has high resistance to corrosion cracking. As the CS API 5L Grb Material is carbon steel, it has high toughness and is resistant to wear and tear.

Mechanical Properties of API 5L Grade B PSL1 Specification

Mechanical Properties PSL 1

Grade

Yield Strength(Min.)

Tensile Strength(Min.)

Elongation

Ksi

MPa

Ksi

MPa

E=1944 A 0.2 /U 0.9

B

35

241

60

414

X42

42

290

60

414

X46

46

317

63

434

X52

52

359

66

455

X56

56

386

60

414

X60

60

414

63

434

X65

65

448

66

455

Mechanical Properties PSL 2

Grade

Yield Strength

Tensile Strength

Elongation

Min

Max

Min

Max

E=1944 A 0.2 / U 0.9

Ksi

MPa

Ksi

MPa

Ksi

MPa

Ksi

MPa

B

35

241

65

448

60

414

110

758

X42

42

290

72

496

60

414

110

758

X46

46

317

76

524

63

434

110

758

X52

52

359

77

531

66

455

110

758

X56

56

386

79

544

71

490

110

758

X60

60

414

82

565

75

517

110

758

X65

65

448

87

600

77

531

110

758